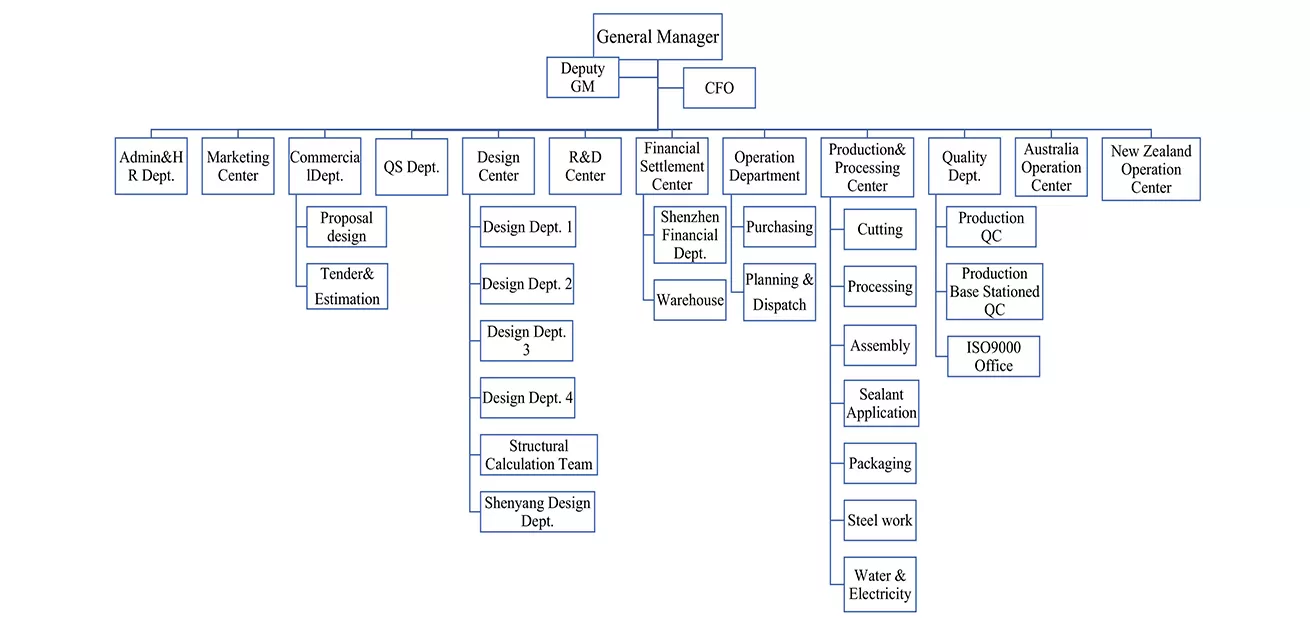

Altop Facade is an integrated one-stop curtain wall solutions provider specializing in energy-efficient windows & doors, aluminum products, stainless steel systems and structural facades. Our 45,000m² modern production base features advanced CNC equipment and automated coating lines, backed by ISO 9001/14001/45001 certifications and Class-A curtain wall qualification. Products are exported to the Middle East, Australia, South America, and Southeast Asia.

For over a decade, we've delivered premium solutions for landmark global projects. Operating with 300+ professionals (50% holding bachelor's degrees or above) and 50+ patented technologies, we uphold the "Integrity & Innovation" philosophy. Moving forward, we'll focus on "New Materials, Premium Quality, Cutting-edge Technology and Intelligent Solutions" to advance sustainable development in building technology.

Our business reaches over 30 countries and regions worldwide, including the Middle East, Australia, New Zealand, South America, Southeast Asia, North America, China, and Japan.

The company is supported by over 50 patented technologies.

Altop operates a 45,000m² modern production base, supporting the global manufacturing of high-quality curtain wall products.

Creating green buildings all over the world and improving the commercial and living environment when improving the spiritual and physical life of employees.

Become a leading enterprise of metal curtain walls integrated system solutions provider.

Customer-centric, Honesty, innovation as source, persistent effort Win-win cooperation, the pursuit of excellence. Let the best employee becoming the company's partner.

Better City, Better Altop.

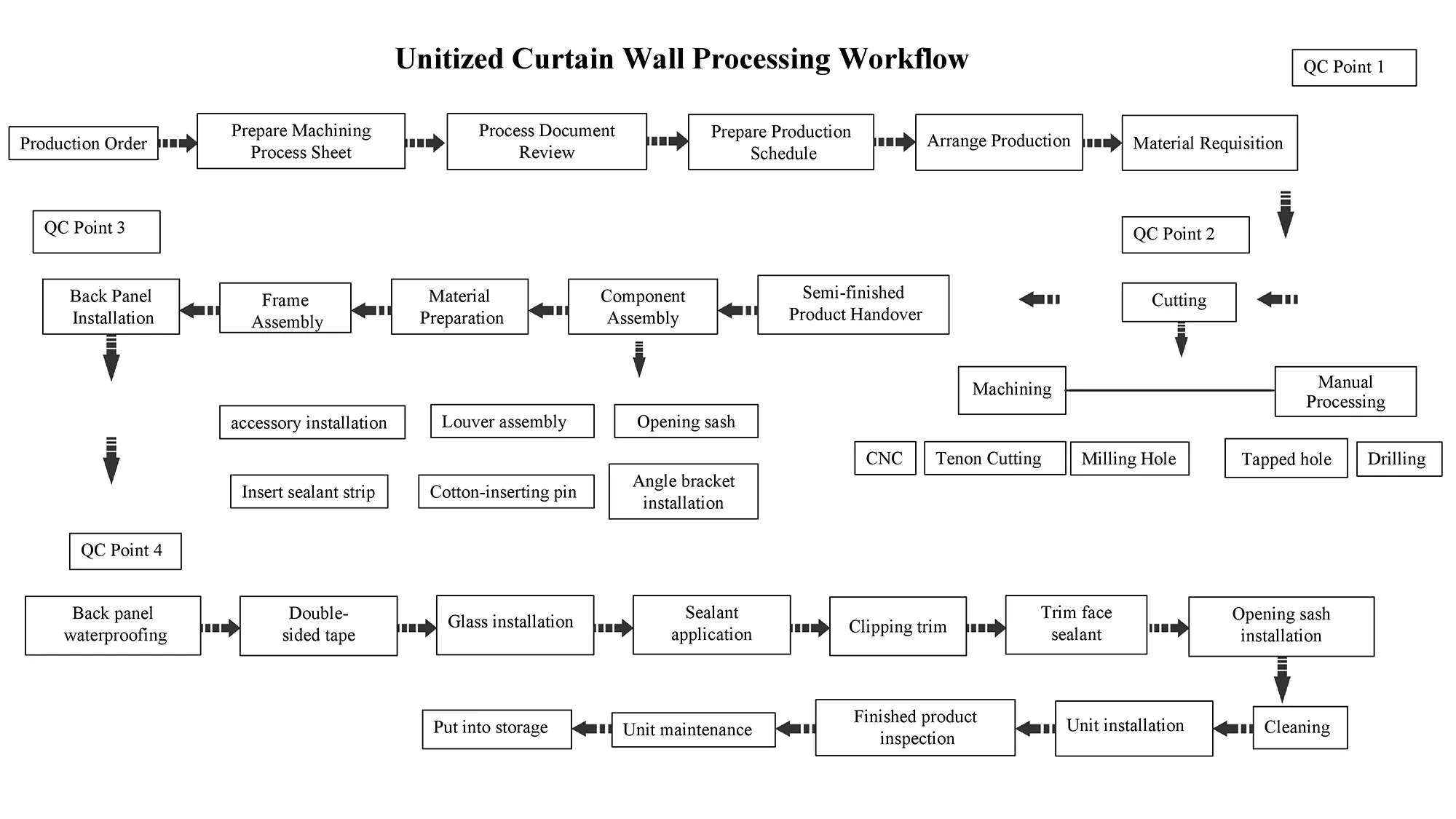

ALTOP follows a strict quality control process from raw material to final delivery. All materials are inspected upon arrival, with non-conforming items rejected. Before mass production, first-piece inspections are conducted to ensure compliance. Throughout production, key steps like cutting, assembly, and sealant application undergo spot checks and are fully documented. Final products are tested for air-tightness, water resistance, and wind pressure. Only after passing all inspections are products packed, checked, and loaded for delivery—ensuring consistent, high-quality standards from start to finish.